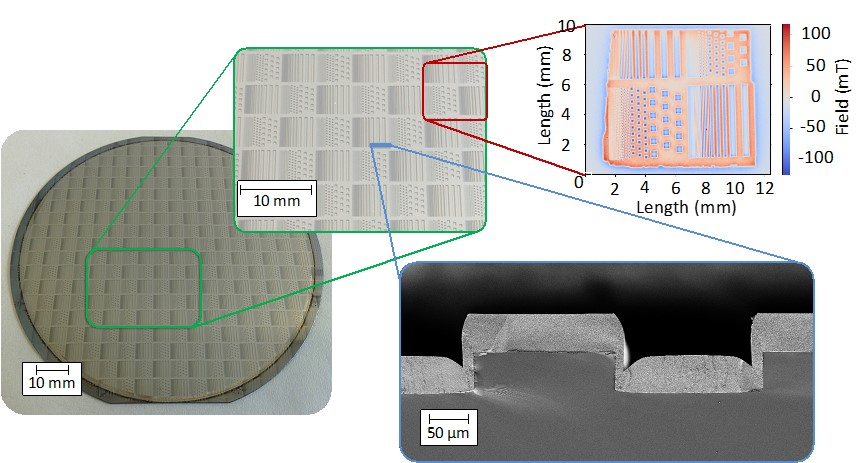

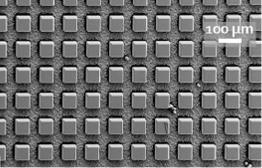

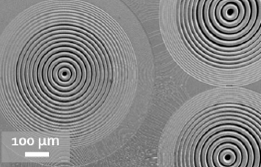

MagnetFab is at the forefront of microtechnology innovation, pioneering the production of integrated micromagnets that are poised to transform the next generation of microelectronic systems. Our micromagnets, made from the strongest known magnetic material, are typically as small as a grain of sand. Comparable magnets with such microscopic dimensions and extraordinary magnetic properties are absent from the market, as traditional magnet manufacturing methods are limited to sizes no smaller than one millimeter.

At MagnetFab, we are breaking this barrier through a revolutionary thin-film technology that enables the production of thousands of integrated micromagnets on a single substrate, similar to how integrated circuits are fabricated. This breakthrough paves the way for cost-effective, high-volume manufacturing and opens new frontiers in microelectronics.